ISI has extensive experience in designing several fracking fluids (fracking) and in carrying out acid stimulation processes by using products manufactured and designed in our plant.

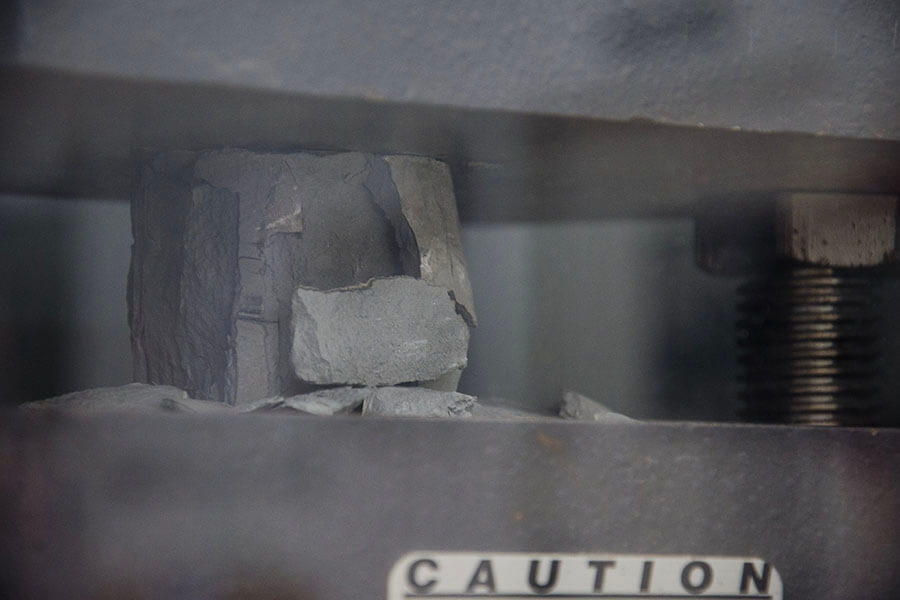

We have a great variety of proppants: natural sands, resign sands and ceramics.

We precisely know which product and system are pertinent to meet your requirements and needs. Same allows us to get a better cost – performance ratio operation.

Gelling agents, Crosslinkers, pH Regulators, Gel Breakers, Bactericides / Biocides, Clay Inhibitors, Surfactants, Proppants, Corrosion Inhibitors, Low and High Viscosity Friction Reducers.