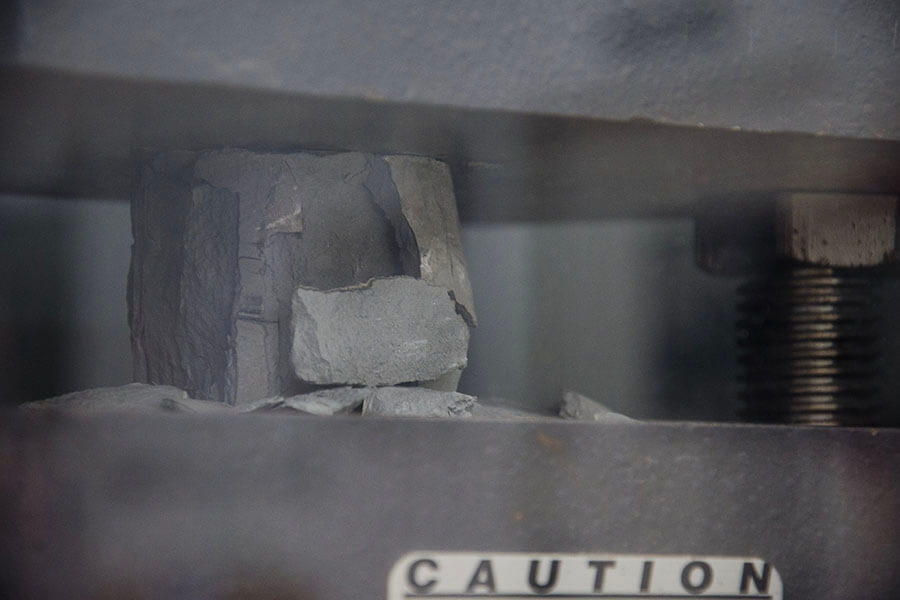

Drilling oil-wells requires reliable and high-performance / high yield products. Isi Oilfield Chemicals has a wide variety of chemicals manufactured in our lab by using lots of local raw material.

Drilling mud quality is essential to reach good oil-well cementation levels and we strongly assure to have what is necessary to guarantee such high quality.

Flocculants, Dispersants, Anti foaming agents, Bactericides / Biocides, Clay Stabilizers, Fluid Loss Controllers, Lubricants, Oxygen Scavengers, Deflocculants, Surfactants.