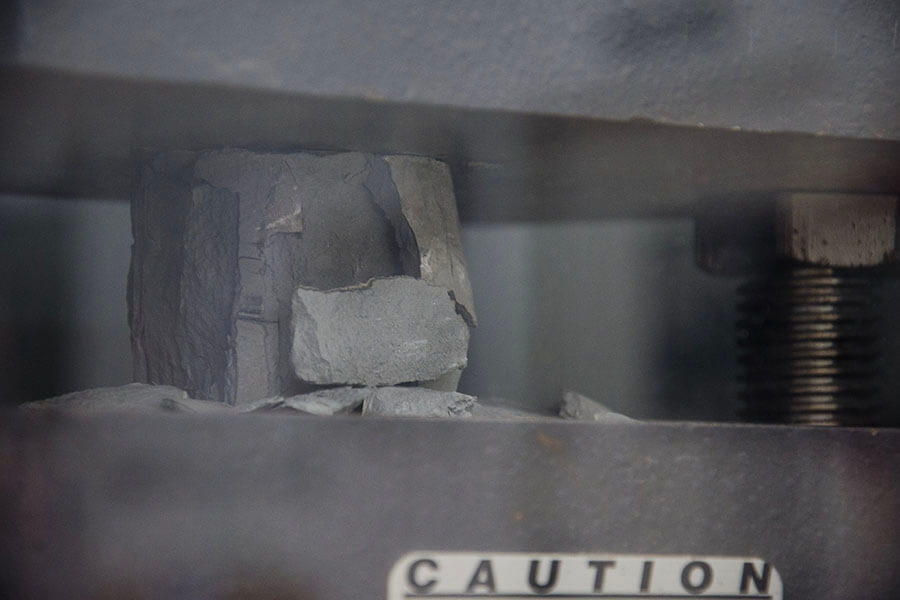

Cementing oil-wells has no hidden secrets for us. In fact, we even design special ultra-low-density slurries that are at high and extreme temperatures or geothermal wells. Such challenges are overcome by applying ISI professionals’ engineering knowledge and processes in our labs.

Antifoaming Agents, Dispersants, Filtering reducers, Thickening Time Retarders, Specials, Lighteners, Expansive Agents, Latices, Anti – Migration Additives.